Improve Bulk Liquid Filling Efficiency; Increase Throughput

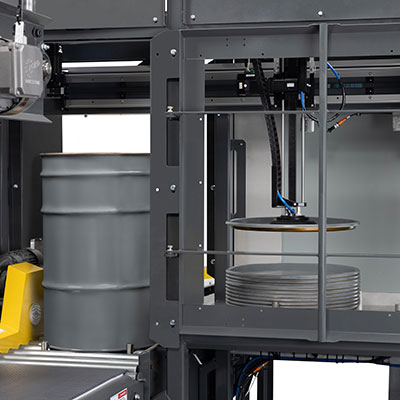

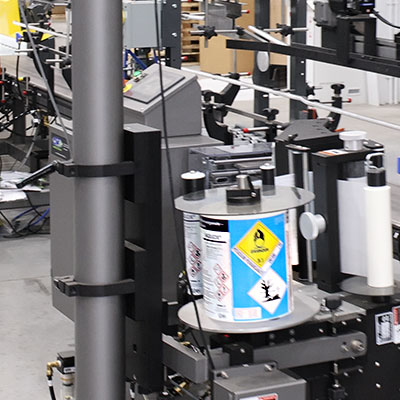

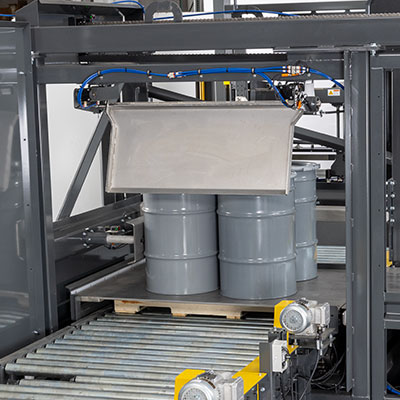

NBE drum and tote filling systems for bulk liquid processing and packaging are engineered-to-application; ensuring process-specific performance metrics are met and optimal total cost of ownership is achieved. From fullstream, high-throughput bulk container filling projects, to liquid filling systems for small-batch, low-rate production, NBE bulk liquid filling and packaging systems for drums and totes enable project owners, AECs, and operations staff to move beyond the constraints of build-to-order units into the performance advantages of NBE engineered-to-application equipment, systems, and projects.

The integrated automation of NBE bulk liquids packaging systems for drums and totes enables packaging operations to run fully automated production at designed speeds without concern for recurring material waste, rework, or excess labor allocation common with under-performing bulk liquids packaging systems.

The integrated automation of NBE bulk liquids packaging systems for drums and totes enables packaging operations to run fully automated production at designed speeds without concern for recurring material waste, rework, or excess labor allocation common with under-performing bulk liquids packaging systems.

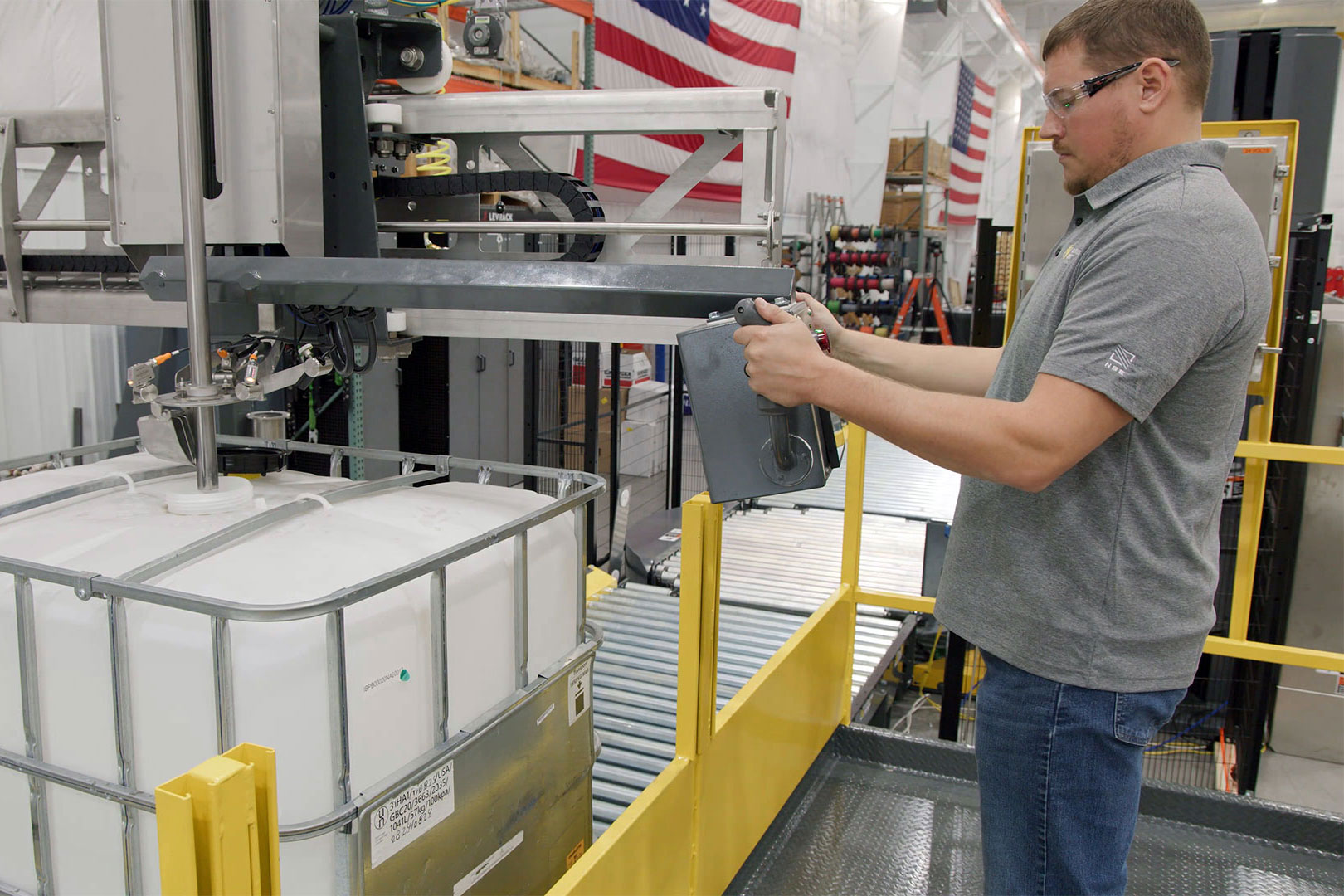

It's the up-front work done by the NBE automation engineering team, regarding area classifications, operator interface standards, EH&S influences, rates, data reporting, and security; that effectively determines the most efficient balance between operator requirements and the NBE drum and tote liquid filling system automation contribution.

It's the up-front work done by the NBE automation engineering team, regarding area classifications, operator interface standards, EH&S influences, rates, data reporting, and security; that effectively determines the most efficient balance between operator requirements and the NBE drum and tote liquid filling system automation contribution.