Increase Liquid Dosing Accuracy; Improve Process Yield

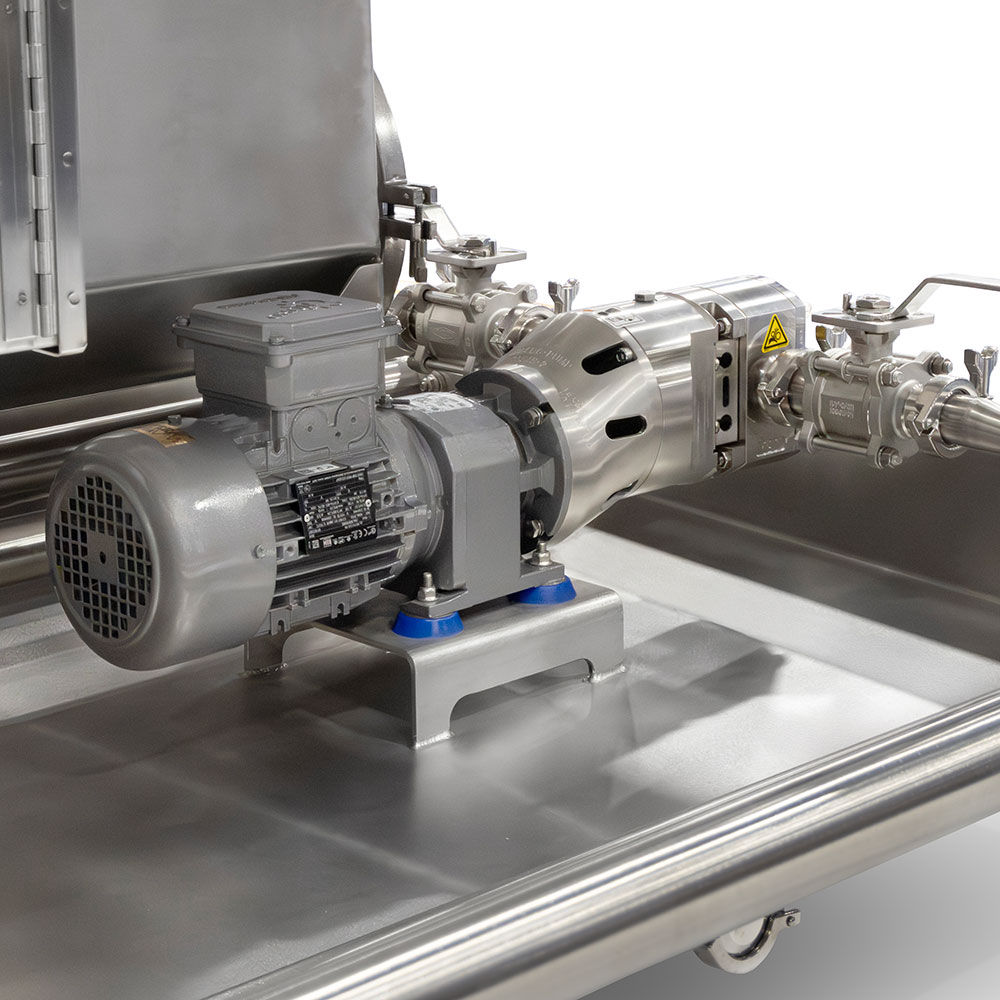

NBE liquid dosing skid systems are engineered-to-application to ensure optimal performance in process operations requiring precision material metering, or processes in which reliable, effective bulk raw material transfer is needed. The application-specific design and build specifications of NBE liquid introduction systems include stainless steel materials of construction for hygienic environments and, for general-industry applications, features such as carbon steel construction and high-rate pump systems provide repeatable downstream material supply.

Sanitary, or general industry, design and build specifications reduce cleaning time; improving labor utilization and total process performance.

Sanitary, or general industry, design and build specifications reduce cleaning time; improving labor utilization and total process performance.

Material metering system ensures highly accurate, material measurements necessary for precise dosing; prevents material waste common with scale systems.

Material metering system ensures highly accurate, material measurements necessary for precise dosing; prevents material waste common with scale systems.

Reservoir provides batch transfer or continuous flow to downstream operations, at designed rate, during replacement of the empty material tote.

Reservoir provides batch transfer or continuous flow to downstream operations, at designed rate, during replacement of the empty material tote.

Engineered-to-application pump, drive, and valve system provides optimal performance in operating efficiency, cleanability, and long-term reliability.

Engineered-to-application pump, drive, and valve system provides optimal performance in operating efficiency, cleanability, and long-term reliability.