Achieve Maximum Throughput with Optimal Accuracy and Rate

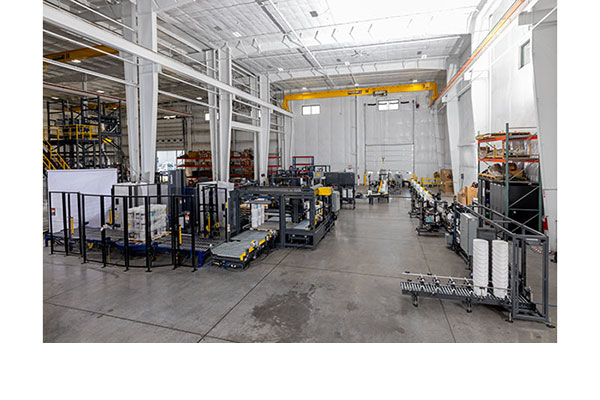

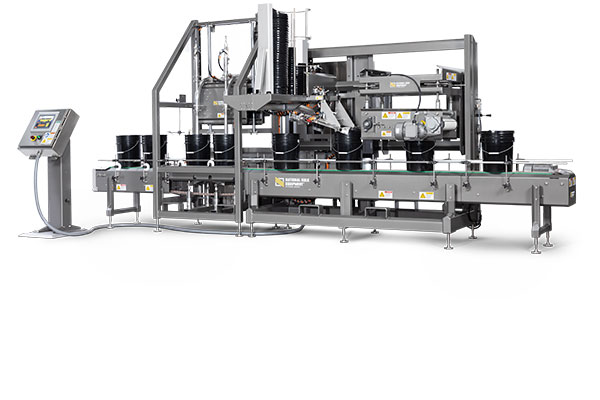

NBE pail filling systems are engineered and built to the particular performance requirements and build specifications of each application. This engineered-to-application project delivery method ensures each NBE pail filling system also contributes to optimizing the performance of upstream and downstream equipment and processes. Regardless of the viscosity, solids concentration, foaming, or temperature of the liquid, NBE pail filling systems deliver highly accurate and repeatable fill cycles at designed throughput and yield.

Automatic Systems

Automatic Systems Semi-automatic Systems

Semi-automatic Systems