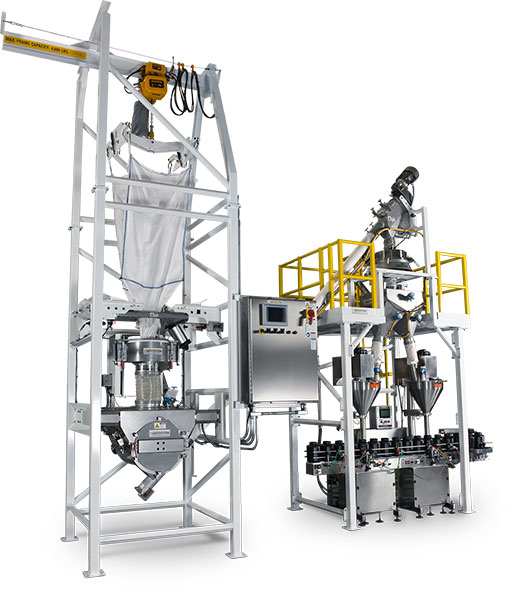

Performance-proven Design and Construction

NBE bulk bag discharger systems are designed for rigorous duty in critical applications. Every NBE bulk bag discharging system, regardless of its particular design or application, operates on a process-specific, fully welded structural framework chassis; unlike the bolt-together unloader designs typical in the market. The NBE integrated construction and controls infrastructure enables all automation and control functions to be centralized to a single, menu-driven HMI. This NBE integrated construction and controls infrastructure provides the basis for reduced total cost of ownership, relative to the common concept of divergent 'islands' of equipment and controls, while also improving process performance and the accuracy of production data shared throughout the enterprise.